Welded Steel Pipes V.S. Seamless Steel Pipes

time2024/05/29

- Seamless pipes and welded steel pipes are two common steel pipe products. In general, seamless pipes and welded steel pipes are different in manufacturing processes, structural characteristics, production costs and uses, so they need to be considered based on specific engineering needs when choosing to use them.

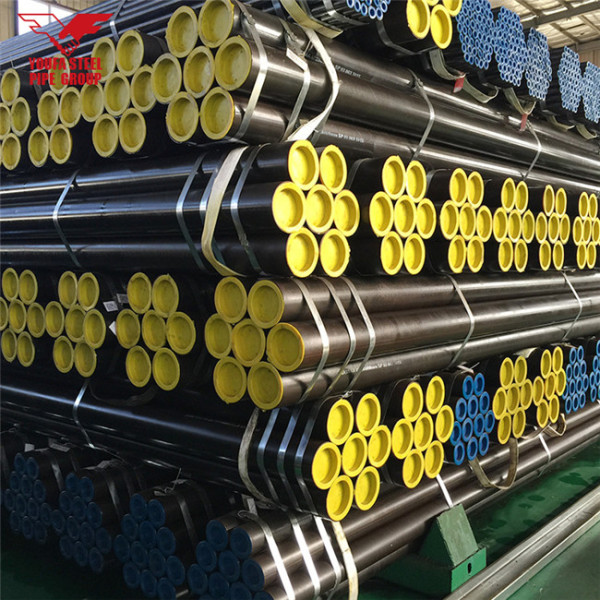

Welded Steel Pipes

Welded Pipes

Welded steel pipe is a steel pipe made by rolling a steel plate into a tube shape and then welding it. During the welding process, the edges of the steel plates are heated to a molten state and then joined together through pressure or filling with welding material to form a continuous tubular structure. There will be welded joints inside the welded steel pipe, which may cause some welding defects. Therefore, in some specific projects, the strength and pressure resistance of the welded steel pipe may be relatively low. Welded steel pipes are usually used in general engineering structures, construction, transporting liquids, gases and other fields.

Raw Material for Welded Steel Pipes

usually steel plate or steel strip. These steel plates or steel strips can be made of different materials such as carbon steel, alloy steel, stainless steel, etc. When making welded steel pipe, steel plate or strip is rolled into a tube shape and then the edges are joined together through a welding process to form the pipe. The selection of raw materials for welded steel pipes depends on the specific use requirements and environment to meet the needs of different engineering projects.

|

There are several types of welded steel pipes Youfa SUPPLY

|

||||

|

Electric Resistance Welded (ERW) Carbon Steel Pipe

|

Spiral Submerged Arc Welded (SSAW) Carbon Steel Pipe

|

Longitudinal Submerged Arc Welded (LSAW) Carbon Steel Pipe

|

Welded Stainless Steel Pipe

|

|

|

This type of pipe is produced by cold-forming a sheet of steel into a cylindrical shape and then welding the seam using an electric current.

ERW pipes are widely used in various industries due to their cost-effectiveness and versatility. |

SSAW steel pipes are produced using a helical welding process. In this method, the steel strip is coiled and welded using a spiral seam, resulting in a strong and durable pipe with a smooth surface finish. SSAW spiral welded steel pipes are commonly used in oil and gas transmission, water transmission, piling, and structural support. The spiral welding process allows for the production of pipes with larger diameters and wall thicknesses, making them suitable for high-pressure and high-stress environments. |

LSAW pipes are produced by bending and shaping steel plates into a cylindrical shape and then welding the seam using a submerged arc welding process.

LSAW steel pipes are often used in large-diameter and high-pressure applications. |

Stainless welded steel pipe refers to a type of pipe that is made from stainless steel and is produced using a welding process to join the metal components. The stainless steel used in these pipes contains a high percentage of chromium, which provides corrosion resistance and durability, making it suitable for a wide range of applications. Stainless welded steel pipes are commonly used in industries such as oil and gas, chemical processing, food and beverage, pharmaceuticals, and construction, where corrosion resistance, hygiene, and structural integrity are essential. These pipes are available in various sizes, grades, and specifications to meet the specific requirements of different applications. |

|

Outside Diameter: 21mm to 660mm | Square: 20x20mm to 500x500mm Rectangular: 20x40 to 300x500mm | Outside Diameter: 219mm to 3048mm | Outside Diameter: 323mm to 1800mm | Round OD: 12.7mm -2032mm Square: 15x15-400x400MM Rectangular: 20x40-300x400MM |

bs1387 schedule 40 21.3mm-219.1mm hot dip galvanized steel pipe q195/235 matrial 6 meter for delivery gas

steel section square tubing wall thickness galvanized square tubing

API 5L X52 od 219-3000mm piling steel pipes SSAW Spiral welded steel pipes for the line pipe of petroleum

Certified: API 5L, ISO

Surface Coating: Epoxy Coating / Colour Paint Coating / 3LPE Coating.

Support: OEM&ODM

Stainless pipes are used to transport various fluids such as water, chemicals, gases, and other liquids in industrial settings

Seamless Steel Pipes

Seamless Pipes

Seamless steel pipe is a steel pipe manufactured through an integral heating and perforation process. It has a uniform internal structure and no welded joints. This kind of steel pipe has the characteristics of high strength and good pressure resistance. It is usually used under high pressure, high temperature and high strength working conditions, such as petroleum, chemical industry, aerospace and other fields. The manufacturing process of seamless steel pipes is relatively complex, so the production cost is high, but it has irreplaceable advantages in some special projects.

Raw Material for Seamless Steel Pipes

usually steel billets, which are produced through steel-making furnaces in steel plants. Steel billets can be produced according to different requirements and standards to meet various uses and specific performance requirements of seamless pipes. Common steel billets include carbon steel, alloy steel, stainless steel, etc. Steel billets of different materials are selected for production according to specific needs and usage environments.

Seamless Carbon Steel Pipes

OD: 1/4 inch to 38 inch

Seamless Stainless Steel Pipes

OD: 6mm - 610mm

Mild Seamless Steel Pipe /Tube Schedule 40/sch std Steel Pipe

A106 SCH40 Carbon Seamless Steel Pipe Oil and Water Steel Pipe

API seamless steel pipe used for petroleum pipeline

Welded Pipes V.S. Seamless Pipes

Seamless pipes and welded steel pipes are two common steel pipe products. There are some differences between them:

Manufacturing process: Seamless pipes are manufactured by overall heating and perforation steel billets, while welded steel pipes are manufactured by rolling steel plates into tube shapes and then welding them.

Structural characteristics: The internal structure of seamless pipes is more uniform and has no welded joints, so it has higher strength and pressure resistance; while welded steel pipes have welded joints inside and may have welding defects, so their strength and pressure resistance are relatively low.

Production cost: Since the manufacturing process of seamless pipes is more complex, the production cost is relatively high; while the manufacturing process of welded steel pipes is relatively simple and the production cost is relatively low.

Usage: Seamless pipes are usually used under high-pressure, high-temperature, and high-intensity working conditions, such as petroleum, chemical industry, aerospace and other fields; while welded steel pipes are widely used in general engineering structures, construction, transportation of liquids, gases, etc. .