-

The application of the steel pipe such as Tianjin welded erw steel pipe is to be widely applied.

time2018/05/14

-

-

-

-

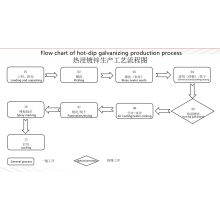

Hot-dip galvanizing production process

time2021/08/20

-

Galvanized Steel Pipe vs. Black Steel Pipe

time2021/08/20

-

Ringlock Scaffolding is the latest wedge lock system which is easy assembly and time saving.

time2021/08/31

-

In the summer, there is a lot of rain, and after the rain, the weather is hot and humid. In this state, the surface of galvanized steel products is easy to be alkalization (commonly known as white rust), and the interior (especially 1/2inch to 1-1/4inch galvanized pipes) is prone to produce black spots due to covering the packaging and lack of ventilation. How to store galvanized steel products during the rainy season ?

time2023/07/04

-

304/304L stainless seamless steel pipe is one of the very important raw materials in the manufacture of stainless steel pipe fittings. 304/304L stainless steel is a common chromium-nickel alloy stainless steel with good corrosion resistance and high temperature resistance, which is very suitable for the manufacture of pipe fittings.

time2023/07/27

-

select the most suitable galvanized pipe fittings for your needs or projects

time2023/12/12

-

what is the difference between hot dip galvanized greenhouse pipe and pre galvanized greenhouse pipe

if you're looking for maximum durability and longevity for your greenhouse, hot dip galvanized pipes are the way to go.

time2023/12/13

-

The term "schedule" refers to the wall thickness of the pipe and is denoted by a numerical value. The thickness of schedule 40 pipe varies depending on the nominal size (diameter) of the pipe. For example, a 2-inch schedule 40 pipe typically has a wall thickness of 0.154 inches (3.91 mm).

time2024/04/19

-

Schedule 80 carbon steel pipe is a type of pipe characterized by its thicker wall compared to other schedules, such as Schedule 40. The "schedule" of a pipe refers to its wall thickness, which affects its pressure rating and structural strength.

time2024/05/24

-

BSP (British Standard Pipe) threads and NPT (National Pipe Thread) threads are two common standards used in various applications to connect pipes and fittings. The main differences between them are as follows:

time2024/05/27

-

The API 5L standard specifies requirements for the manufacture of two product specification levels (PSL) of line pipe for use in the transportation of gas, water, and oil in the petroleum and natural gas industries. These two specification levels are PSL1 and PSL2, which have different requirements for various properties.

time2024/05/28

-

Seamless pipes and welded steel pipes are two common steel pipe products. In general, seamless pipes and welded steel pipes are different in manufacturing processes, structural characteristics, production costs and uses, so they need to be considered based on specific engineering needs when choosing to use them.

time2024/05/29

-

It’s important to note that the theoretical weight is an estimate based on the dimensions and density of the steel, while the actual weight is the physical weight of the pipe. The actual weight may vary slightly due to factors such as manufacturing tolerances, surface finish, and material composition.

time2024/06/12

-

Stainless steel is a material widely used across various industries, renowned for its corrosion resistance and versatility. Among the numerous grades of stainless steel, 304, 304H, 304L, and 316 are the most common, as specified in the ASTM A240/A240M standard for “Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and General Applications.”

time2024/09/24

-

Today galvanized pipe is no longer prohibited from being used for natural gas. "Steel pipe must be Schedule 40 or heavier, must comply with one of the listed standards and can be black iron or galvanized. Contrary to popular belief, natural gas does not adversely react with the zinc coating on galvanized pipe".

time2024/12/27

-

Black steel pipe is cheaper than galvanized pipe. This is due to the zinc coating on galvanized pipe and the manufacturing process making it. Black steel pipe is darker than galvanized pipe; it is flat black while galvanized pipe is silver and gray. Black pipe is ordinary iron pipe used by businesses and residences to carry natural gas or propane gas supplies. Galvanized pipe is usually applied for water carriage.

time2024/12/27

-

Both "Feet" and "foot" are words used to represent units of length. "Foot" is an imperial unit of length, represented by the symbol "ft", and when expressed in the plural, it is "feet". 1 foot =12 inches.

time2025/03/17

-

Summer Storage Tips for Galvanized Steel-Plastic Products During the Rainy Season

In the hot summer months, frequent rainfall and subsequent humid conditions can easily cause galvanized products to develop surface alkali efflorescence (commonly known as white rust). Therefore, dear customers (both new and returning), it’s essential to keep in mind the following storage tips for galvanized products during the rainy season!time2025/06/23

-

Beveling carbon steel pipes ensures deeper weld penetration, stronger joints, and longer-lasting performance, making it essential for industrial and structural applications.

time2025/06/24

-

Stainless steel has the ability to resist corrosion by forming a thin, strong, and stable oxide film (protective film) on its surface, which prevents oxygen atoms from continuing to infiltrate and oxidize. Once for some reason, this thin film is continuously damaged, oxygen atoms in air or liquid will continuously infiltrate, or iron atoms in metal will continuously be damaged, forming loose iron oxide, and the metal surface will also be continuously corroded.

time2025/08/27

-

The reason why stainless steel is resistant to corrosion is that it has a dense layer of Cr203 on its surface, which must be in contact with oxygen to form. Decorative stainless steel can maintain its brightness and rust resistance for a long time as it is used and maintained properly.

time2025/08/27

-

Youfa brand scaffolding pipes are hot sale in China, UK, UAE and many countries. EN 39, BS 1139, BS 1387, GB/T 3091, GB/T 13793. We also supply other scaffolding accessories for one- stop purchase service.

time2025/10/17