2 inch Fire Sprinkler Pipe Sch5 with grooved pipe

- FOB Price

US $790.01 - 25 ton

- group name

- Grooved End Steel Pipe

- Min Order

- 5 ton

- brand name

- Youfa Steel Pipe Manufacturer

- model

- grooved Fire Sprinkler Pipe

- Nearest port for product export

- Tianjin Port, Shanghai Port,etc.

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Sun, 01 Mar 2026 05:48:33 GMT

Paramtents

Technic Standard ASTM A53 , ASTM A795

Pipe Length 5.8m, 6m, 6.4m, 7.3m, 19ft, 20ft, 21ft, 24ft

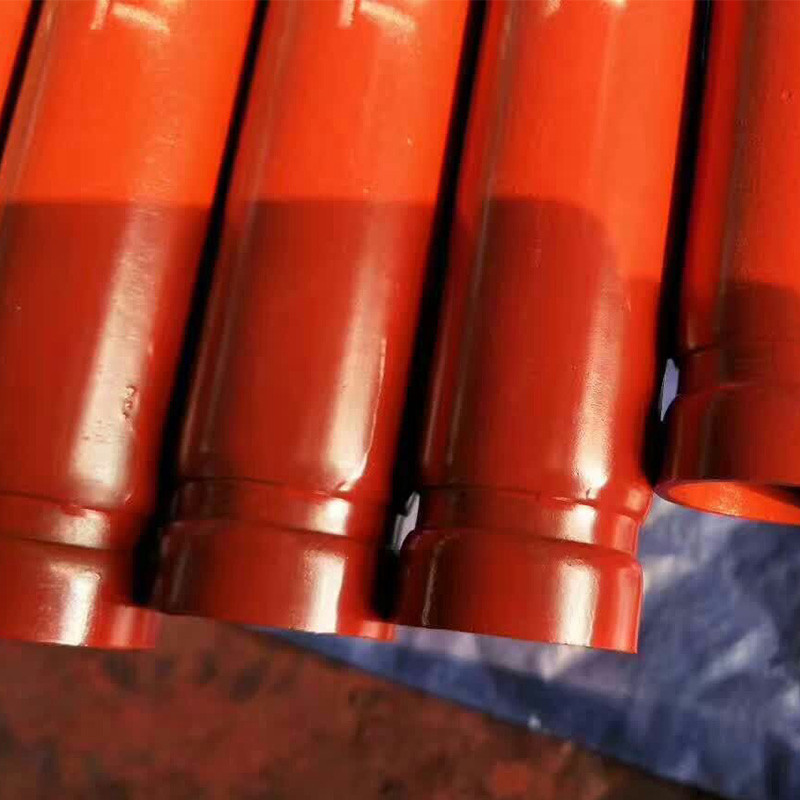

Other surface finished painted red color RAL3000 , Galvanized and then painted red color, black color painted, epoxy coated, anti-rust oiled , or bare no surface treatment

About surface finished the surface finished can be specified by customers

Product name Steel Pipe with grooved ends

Packging & Delivery

-

Min Order5 ton

Briefing

2 inch Fire Sprinkler Pipe Sch5 with grooved pipe

Detailed

Fire Sprinkler Steel Pipe General Product Information

Fire sprinkler steel pipes are typically made of carbon steel and are used to distribute water or other fire suppressant agents throughout a building in the event of a fire. The steel pipes are manufactured to meet specific standards and regulations, such as ASTM A795 and ASTM A53, to ensure steel pipes reliability and effectiveness in fire protection applications.

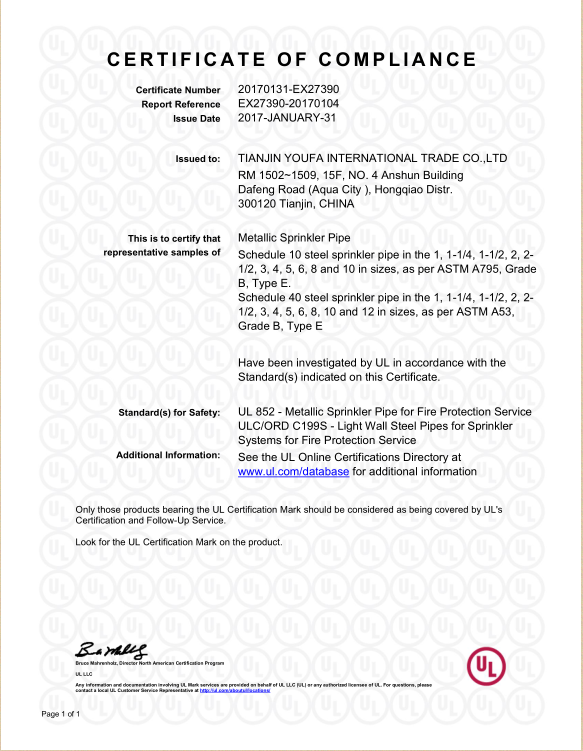

Youfa brand carbon steel welded pipes sch10 and sch 40 carry certifications from organizations FM Global or UL to ensure compliance with rigorous fire safety and performance standards.

|

Commodity

|

Fire sprinkler ERW carbon steel pipes |

|

Usage | construction, building material, fire sprinkler steel pipeline | |

|

Size

|

1/2''-8'' (round hollow)

|

|

Wall thickness | 1.3mm-10mm | |

Length | 5.8m, 6m or cut into other length according to PI | |

Certificates international standard | ISO 9000-2001, UL certificate | |

Standards | ASTM A795, ASTM A53, GB/T3091, etc | |

|

Technique

|

Welded

|

|

Surface | Galvanized or Painted to prevent the rust | |

Pipe ends | Plain or threaded with sockets/coupling and plastic cap or grooved with caps | |

|

Packing

|

In bundles, or request.

|

|

Marking | As requested in PI, for example "UL LISTED YOUFA SCH10 / SCH40" | |

ASTM A795 ERW Carbon Steel Tube Standard Specifications Reference

NPS | DN | Outer Diameter(mm) | Schedule 10 | Schedule 40 | ||||

Wall Thickness (mm) |

Unit Weight (kg/m) | Test Pressure (kpa) | Wall Thickness

(mm) | Unit Weight

(kg/m) | Test Pressure (kpa) | |||

|

1/2"

|

15

|

21.3 |

-

|

- | - | 2.77 | 1.27 | 4800 |

|

3/4"

|

20

|

26.7 | 2.11 |

1.28 | 4800 | 2.87 | 1.69 | 4800 |

1" | 25 | 33.4 | 2.77 | 2.09 | 4800 | 3.38 | 2.50 | 4800 |

1-1/4" | 32 | 42.2 | 2.77 | 2.69 | 6900 | 3.56 | 3.39 | 6900 |

1-1/2" | 40 | 48.3 | 2.77 | 3.11 | 6900 | 3.68 | 4.05 | 6900 |

2" | 50 | 60.3 | 2.77 | 3.93 | 6900 | 3.91 | 5.45 | 6900 |

2-1/2" | 65 | 73 | 3.05 | 5.26 | 6900 | 5.16 | 8.64 | 6900 |

3" | 80 | 88.9 | 3.05 | 6.46 | 6900 | 5.49 | 11.29 | 6900 |

4" | 100 | 114.3 | 3.05 | 8.37 | 8300 | 6.02 | 16.09 | 8300 |

5" | 125 | 141.3 | 3.40 | 11.58 | 8300 | 6.55 | 21.79 | 8300 |

6" | 150 | 168.3 | 3.40 | 13.85 | 6900 | 7.11 | 28.29 | 8300 |

8" | 200 | 219.1 | 4.78 | 25.26 | 5500 | 8.18 | 36.82 | 8300 |

Pls don't hesitate to contact us if you need other sizes. | ||||||||

ERW Carbon Steel Fire Sprinkler Pipes Surface and Pipe Ends

Surface: Painted Ral3000 or other color

Pipe Ends: Grooved with caps

Surface: Zinc coated 30um or above

Pipe Ends: Grooved with caps

Surface: Zinc coated 30um or above

Pipe Ends: NPT threaded with coupling and cap

Surface: Painted Ral3000 or other color

Pipe Ends: NPT threaded with coupling and cap

ASTM A795 Fire Sprinkler Pipes Test and Quality Control

Chemical Composition |

for Type E (electric-resistance-welded pipe)

|

|||

|

C, Max, %

|

Mn, Max, % |

P, Max, %

|

S, Max, %

|

|

|

Grade A

|

0.25

|

0.95 |

0.035

|

0.035

|

|

Grade B

|

0.30

|

1.20 |

0.035

|

0.035

|

Mechanical Properties |

for thickness sch10 and sch40

|

||

|

Tensile strength, min [MPa]

|

Yield strength, min [MPa]

|

Elongation, min, %

|

|

|

Grade A

|

330

|

205

|

24

|

|

Grade B

|

415

|

240

|

24

|