API 5L LSAW Steel Pipe for Oil and Gas Deilvery

- group name

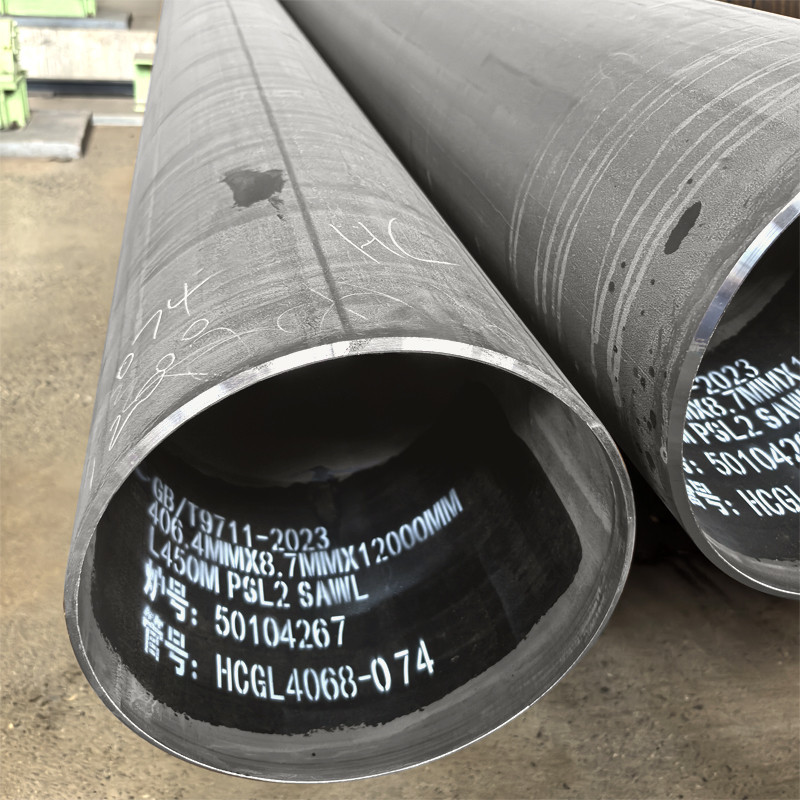

- LSAW Steel Pipe

- Min Order

- 25 metric ton

- brand name

- Youfa Steel Pipe Manufacturer

- Nearest port for product export

- Tianjin Port, Shanghai Port,etc.

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Tue, 03 Mar 2026 00:06:41 GMT

Paramtents

Grade B MOQ One container

Common Steel Grade Grade A and Grade B, S235 and S355JR

Customized Steel Grade Max. X80

Certificates ISO API CE

Structrue Pipe Standards ASTM A252 EN10219 for pipe pile

Oil and Gas Pipeline Standards API 5L GB/T 9711-2023 for petroleum and gas

Packging & Delivery

-

Min Order25 metric ton

Briefing

LSAW pipes for petroleum and natural gas industries

Detailed

LSAW pipes are a premium-grade, high-strength product manufactured with a high-integrity welding process specifically designed for the most demanding and critical applications in energy and infrastructure

LSAW Weld Pipe Products Range

JCOE production line

Outside Diameter: 20"-56"

Wall Thickness: 8-50MM

Steel Grade MAX.: X80

Standard: API Spec 5L with Annex H

Alloy Standard: ASTM A671 / A672 / A691

Structure Standard: EN10219 / ASTM A252

JCOE LSAW production line

Outside Diameter: 16"-40"

Wall Thickness: 6-25MM

Steel Grade MAX.: X70

Standard: API Spec 5L with Annex H & J

Alloy Standard: ASTM A671 / A672 / A691

Structure Standard: EN10219 / ASTM A252

COATING production line

Outside Diameter: 16"-56"

Wall Thickness: 6-50MM

Steel Grade MAX.: X80

Standard: 3LPE DIN30670/CSA Z245.21

3LPP DIN30678/ ISO 21809

FBE CSA Z245.20/DEP 31.40.30.32

LSAW Welded Steel Pipe Quality Control

It is our responsibility and mission to provide customers with stable quality, safe and reliable products. Our factory has a national CNAS laboratory, with perfect testing methods, and implements traceability quality inspection from raw material procurement to manufacturing and finished products leaving the factory to ensure that products meet national standards and meet customer needs.

● Raw material inspection

● Process inspection

● Finished products inspection

● Final inspection and document filing

We fully implement effective product quality control, and runs the nine "100% controls" through every part of the production inspection process.

▣ Raw Material

100% recheck rate of physical and chemical analysis of raw materials

▣ Steel Plate

100% ultrasonic flaw detection rate of steel plate

▣ Steel Pipe

100% hydrostatic test rate of steel pipe

▣ Welding Seam

100% ultrasonic flaw detection rate of all welding seam

▣ Welding Seam

100% x-ray inspection of all welding seam

▣ Welding Seam

100% physical and chemical detection rate of steel pipe and welding seam

▣ Pipe Size

100% detection rate of steel pipe size

▣ Pipe Appearance

100% detection rate of steel pipe appearance quality

▣ Pipe Packaging

100% detection rate of steel pipe packaging

LSAW Steel Pipe Certificates

We have established a complete quality, safety, environment and management certification system, and won many international product certifications such as American petroleum institute API, EU CE-CPR, EU CE-PED and Russian EAC. From R&D, design, production and processing to testing and delivery of products, we implement a traceability management system and adopts 100% quality control for all key processes, so that everything can be traced.

* ISO9001&ISO14001&ISO45001 HSE System.

* API Spec 5L with Sour service for linepipe.

* CE marking for EU CPR&PED pipe.

* ISO17025 for laboratory.

LSAW Pipes Approval List

Client: ADNOC and many EPC at home and abroad.

Chinese market: Shortlisted in the purchasing lists of large domestic enterprises such as PetroChina, Sinopec, CNOOC, CAO, China Gas, China Chemical and Xinao Gas.

International market: supplied oil and gas pipeline to TOTAL, SAIPEM, BP, LukOil, Toyota and PSOCO and many other world's top 50 companies.

Contact with us freely to learn more about our lsaw steel pipes approval list.